Offer

Learn about our range of services and create a tailor-made solution with us.

Rapid Prototyping allows for a fast quotation and production of your project in a version suitable for verification. Contact us via the form, and our specialists will prepare a cost estimate and get in touch to determine the next steps.

Comprehensive services of SMT design and surface mount assembly, THT assembly, AOI, X-Ray inspection, testing and purchase of components.

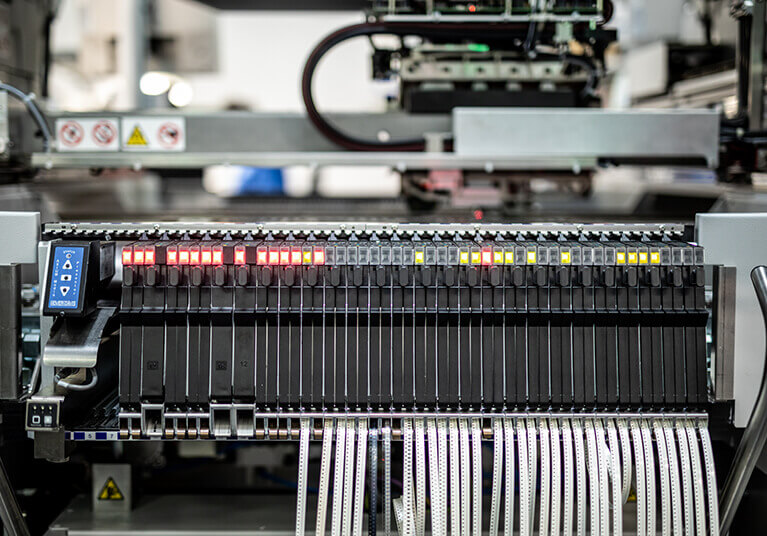

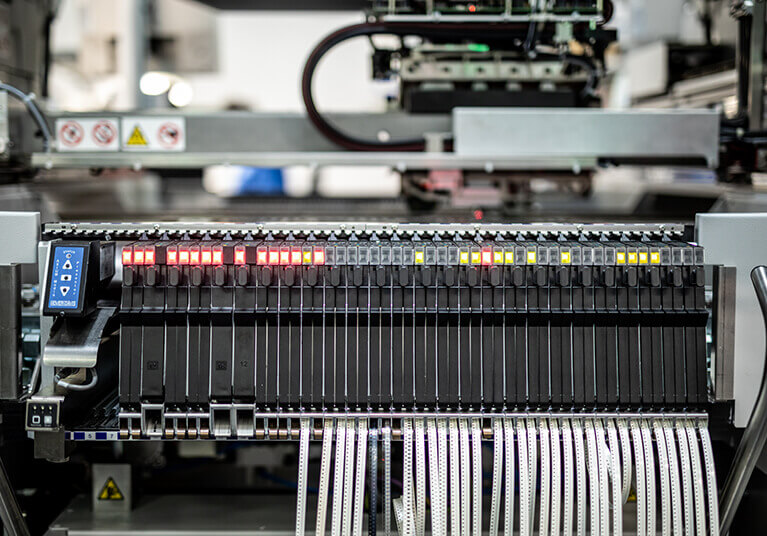

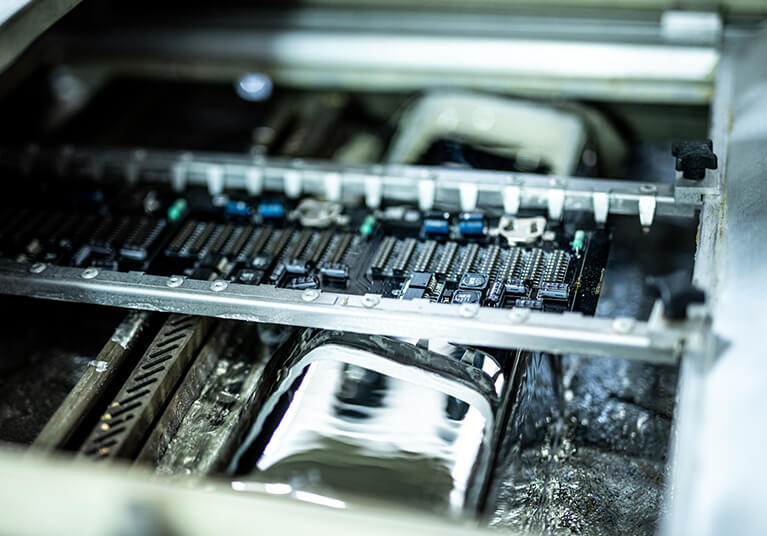

SMT (Surface Mount Technology) assembly is a key process in high-volume electronics production. It is much more efficient and faster than the THT (Through-Hole Technology) assembly, and the use of this technology significantly reduces the cost of manufacturing the product.

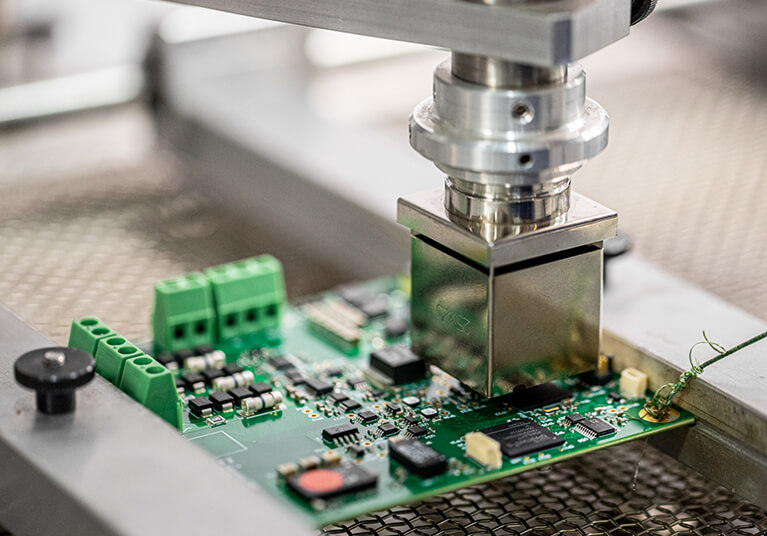

We have two fully automated SMT production lines offering our customers optimisation of the time necessary for assembly and quality control and, above all, reduction of production costs. The performance of each line at the level of 40,000 components per hour, handling 200 different components simultaneously, the possibility of mounting components from 01005, the assembly of fine-grained BGA components and full traceability. In addition, 3D optical inspection (AOI) provides constant monitoring throughout the process.

The machines are based on solutions that allow for quick changeovers, and a wide range of feeders allows for very high flexibility when executing production orders.

In order to provide our customers with a comprehensive service, Novatronik also offers an additional service to expand SMT production capabilities. The Recco RS300 mounting and dismounting device allows you to work with CHIP, SO, QFD, PLCC and BGA components.

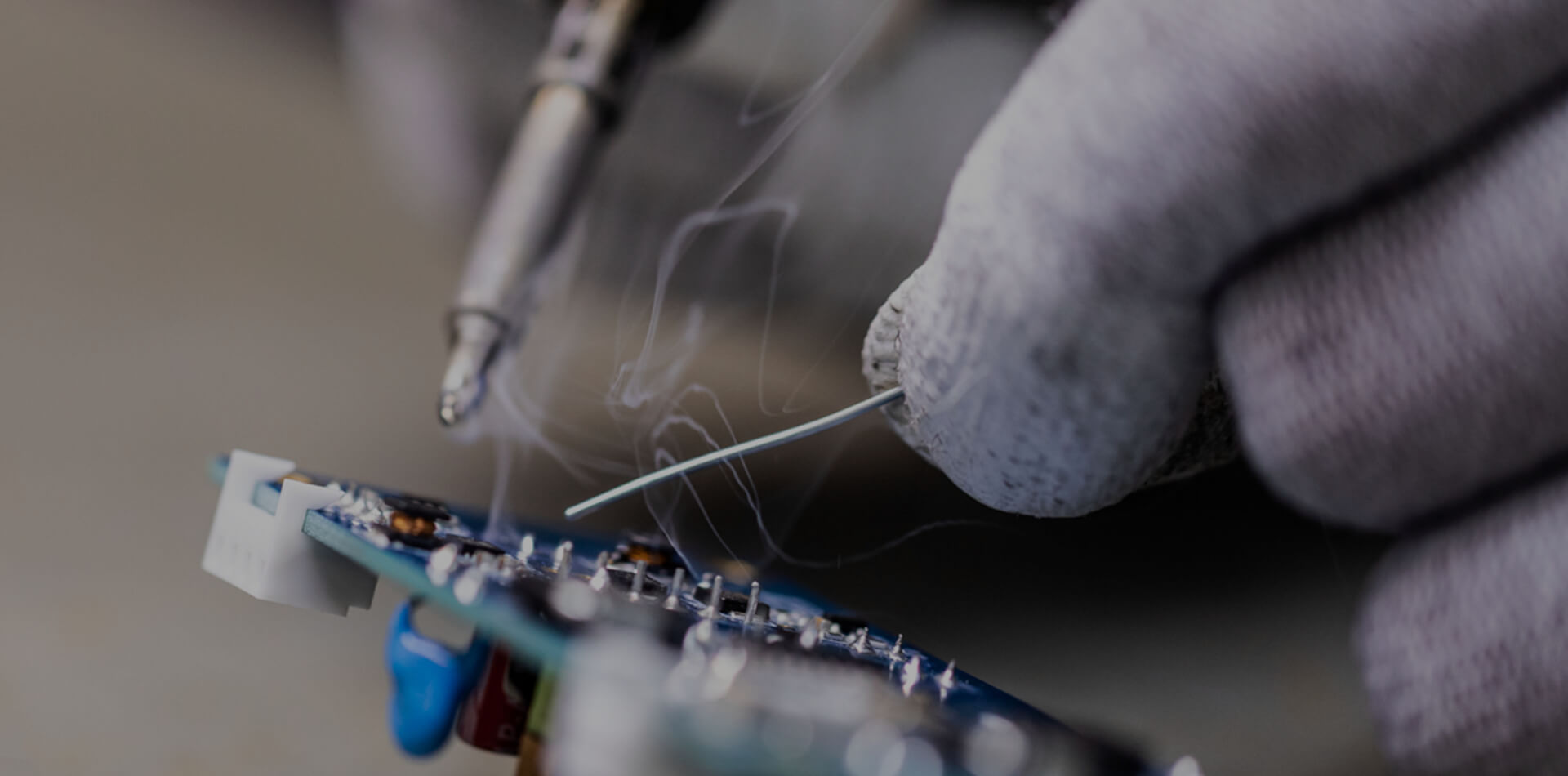

Service of assembly of through-hole components based on selective and wave soldering and a team of experienced IPC specialists.

THT assembly services at Novatronik are performed by highly qualified and experienced IPC specialists, maintaining impeccable standards of precision and repeatability. The assembly involves the wave and selective soldering processes depending on the type of project. Preparation of the material prior to the soldering process is carried out using adjustable automatic tools. The process is 100% controlled for assembly quality according to IPC 610.

Rapid Prototyping allows for a fast quotation and production of your project in a version suitable for verification. Contact us via the form, and our specialists will prepare a cost estimate and get in touch to determine the next steps.