Quality

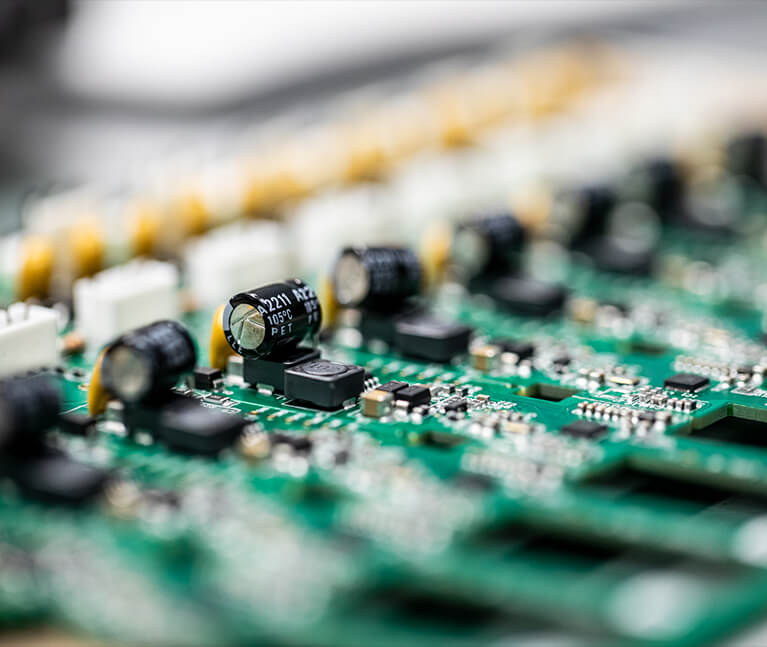

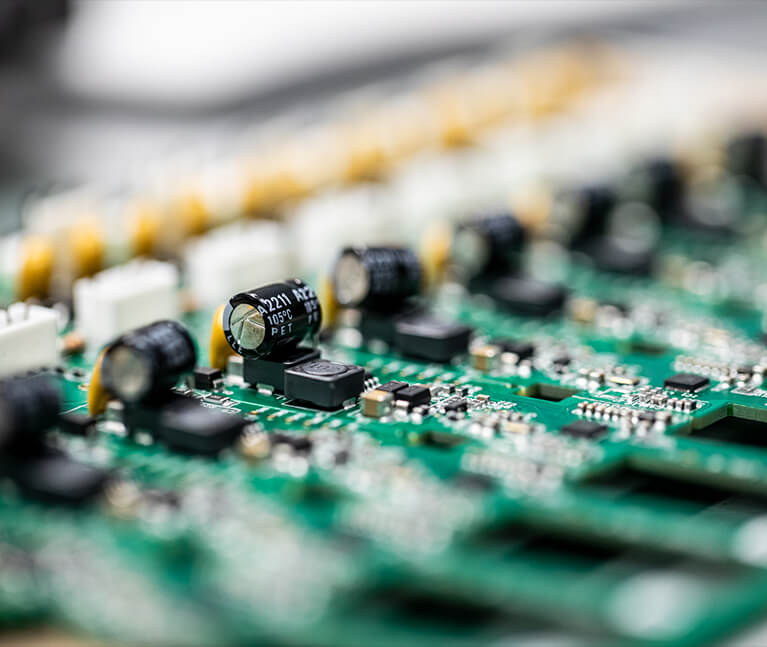

Installation of electronics in accordance with IPC and ISO international standards. EMS contract manufacturing for the automotive, people and property protection, medical and industrial sectors.

Our production is based on the Integrated Management Systems: ISO 9001:2015 (quality management), ISO 14001:2015 (environmental management) and ISO 45001:2018 (occupational health and safety management).

In addition, the devices manufactured for our customers are subject to supervision and periodic audits carried out by international certification bodies Intertek and DEKRA.

Our employees are trained in IPC 610 and 7711/7721.

We manufacture products that meet the Railway Industry Standard (IRIS) and UL electronic standards for the USA and Canada.

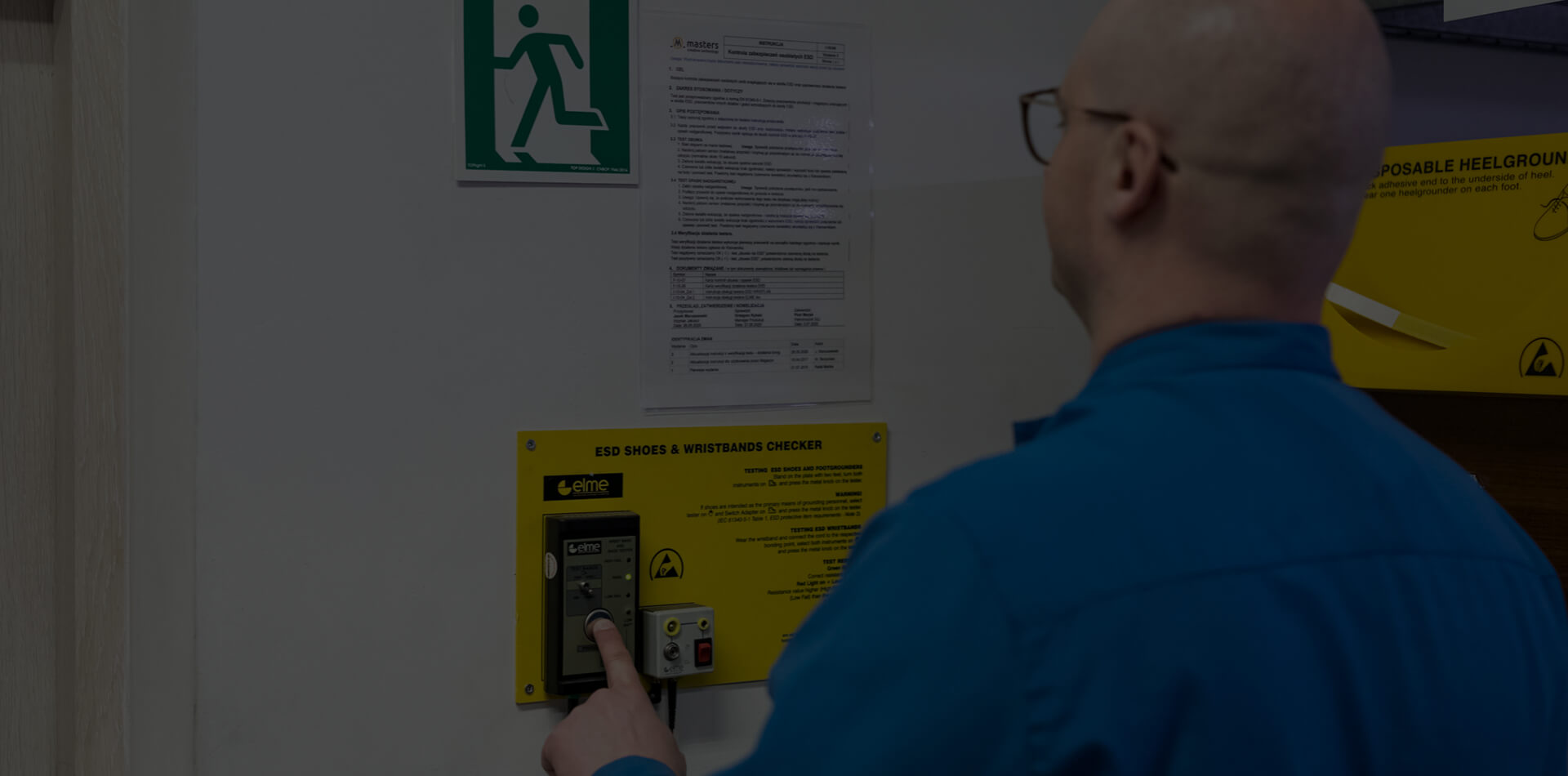

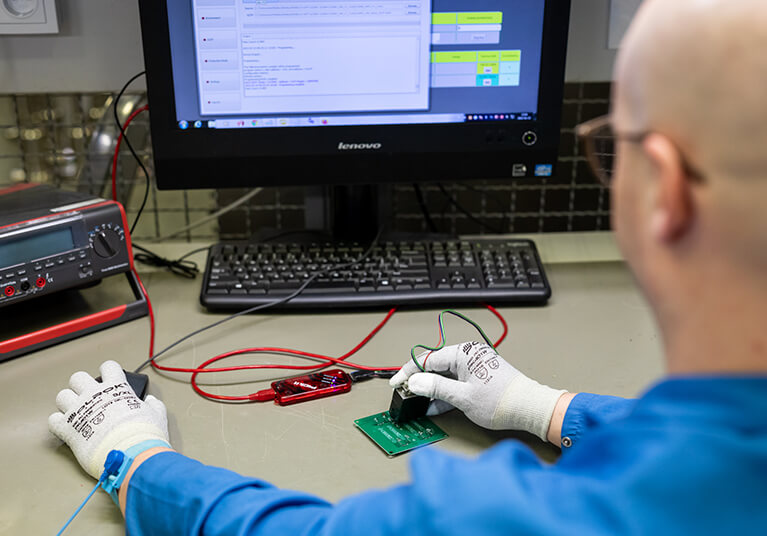

Comprehensive quality control of orders at every stage of the production cycle. Delivery inspection, first article inspection, automatic paste inspection, electrical tests, UV coating verification and traceability. We provide MSL storage conditions in accordance with J-STD 033BO1, as well as ESD audits in accordance with PN-EN 61340-5.

In the inspection process, we use 3D automatic optical inspection (AOI), which is an integral part of the process on both SMT lines, providing constant monitoring of quality maintenance with the qualification and module separation process.

Using our proprietary Manufacturing Execution System (MES), we ensure product traceability at every stage of the process, supervision over the flow of documentation and revisions and preview of the implementation of production orders in real time.

We are systematically adapting our production to global environmental challenges, switching to renewable energy and minimising the carbon footprint of our products. Our factory is powered by solar energy, we reduce greenhouse gas emissions, and we also run a modern waste management.